Warehouse & Fulfillment Insights

Expert insights on warehousing, order fulfillment, assembly, and logistics from Midwest AWD.

Best Practices for Cycle Counting

Cycle counting is a method of maintaining accurate inventory records without shutting down operations for a full physical inventory count. Instead of stopping everything to tally every item at once, warehouses and distribution centers conduct smaller, scheduled counts of specific items or warehouse zones and bins. This ongoing process keeps inventory levels accurate while minimizing ... Best Practices for Cycle Counting

What Is Fill Rate? (And How to Calculate It)

Fill rate is one of the most critical supply chain metrics for any company that stores, moves, or sells physical products. Essentially, it reflects the percentage of customer orders fulfilled completely and on time, making it a direct measure of order fulfillment performance. A high fill rate not only improves customer satisfaction but also ... What Is Fill Rate? (And How to Calculate It)

Fulfillment Centers vs. Distribution Centers

Understanding the difference between a fulfillment center vs. distribution center is critical for any inventory specialist, warehouse manager or e-commerce business owner making decisions about inventory flow, labor needs and customer satisfaction. Though the terms are sometimes used interchangeably, these facility types serve distinct roles in the supply chain. A fulfillment center is optimized ... Fulfillment Centers vs. Distribution Centers

Why Use a 3PL for Subscription Box Fulfillment?

As subscription boxes increase in popularity, the businesses behind them are growing rapidly. With that growth comes the challenge of keeping up with orders. Not only can the increasing demands of order fulfillment distract from core business functions like marketing, customer retention, and product development, but without a proper system in place, essential aspects of ... Why Use a 3PL for Subscription Box Fulfillment?

First In, First Out (FIFO) Inventory Flow

In the world of warehousing and distribution, how inventory flows through your facility can make or break operational efficiency. The FIFO method — short for First In, First Out — is a tried-and-true strategy that prioritizes using or shipping older items before newer ones. It’s essential for maintaining product freshness, reducing spoilage, and staying ... First In, First Out (FIFO) Inventory Flow

Why Average Inventory Matters

No inventory = no sales. Too much inventory = lost profits. Much like the porridge of Goldilocks’ fame, companies must get inventory levels “just right.” If purchases exceed incoming and stored inventory, businesses face stockouts and customer frustration. If goods sit on shelves without being purchased, warehouses and distributors are paying to store products that ... Why Average Inventory Matters

How 3PLs Streamline Returns Management

Ecommerce has become a part of everyday life, gaining significant ground in the last few years alone, and showing no signs of stopping. With this increase in ecommerce comes an increase in returns, and thus, an increase in the need for efficient returns management. Mass returns can become overwhelming without proper support, leading to lost ... How 3PLs Streamline Returns Management

How To Create SKU Numbers: A Comprehensive Guide For Effective Inventory Management

Introduction to SKU Numbers SKU numbers, or stock keeping units, are a critical component of inventory management for any business that sells physical goods. These alphanumeric identifiers help track products throughout the supply chain, from warehouse shelves to customer orders. By assigning a unique SKU code to each product variant, businesses can manage stock levels ... How To Create SKU Numbers: A Comprehensive Guide For Effective Inventory Management

What Is Cross-Docking?

Speed and efficiency are essential for success in today’s logistics landscape. Whether you’re managing retail replenishment or overseeing 3PL eCommerce fulfillment, optimizing the movement of goods through the supply chain is key. That’s where cross-docking comes in — a method designed to minimize delays, reduce warehousing costs, and enhance customer satisfaction through streamlined distribution. So, ... What Is Cross-Docking?

Ultimate Guide To FBA Prep

Selling on Amazon through the Fulfillment by Amazon (FBA) program allows sellers to scale their businesses efficiently, but success depends on preparing inventory correctly before it reaches a fulfillment center. Amazon enforces strict compliance requirements, and failure to meet them can result in delays, penalties, or rejected shipments. Proper FBA prep helps sellers avoid inventory ... Ultimate Guide To FBA Prep

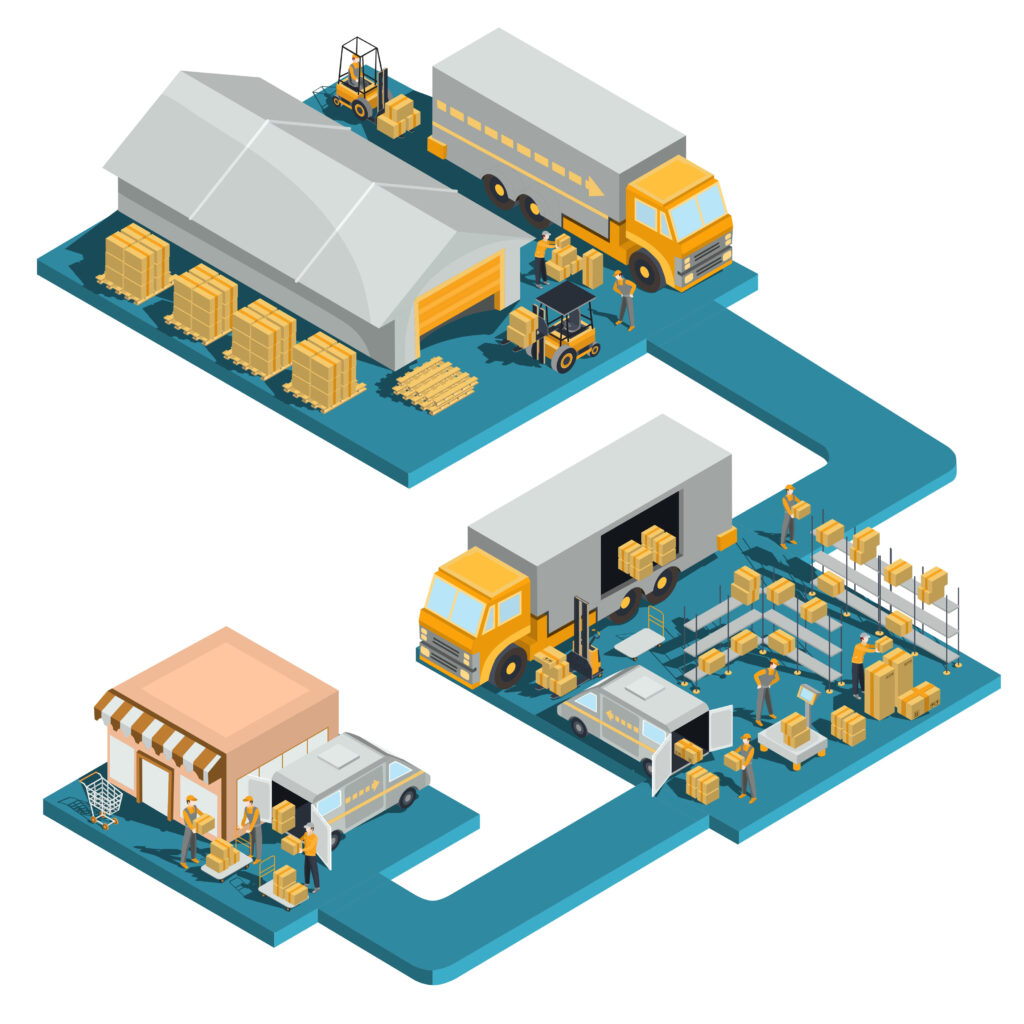

The Connection Between Warehousing and Distribution

Warehousing and distribution are closely linked in supply chain management. Warehousing involves the storage, organization, and management of goods, while distribution focuses on efficiently getting those goods from the warehouse to retailers or customers. Together, they ensure products are stored properly and delivered on time, helping businesses meet consumer demand and maintain smooth operations. In ... The Connection Between Warehousing and Distribution

Calculating Warehousing Costs

Check out our warehouse space calculator here! One of the most commonly asked questions by those looking to partner with commercial storage facilities is how warehousing costs are calculated. When it comes to warehousing, prices are dependent upon more than just the amount of storage space being used. Every decision made in a warehouse has ... Calculating Warehousing Costs